Welcome to Stainless Steel Jewelry Factory Shenzhen YIBI Jewelry Co., Ltd.

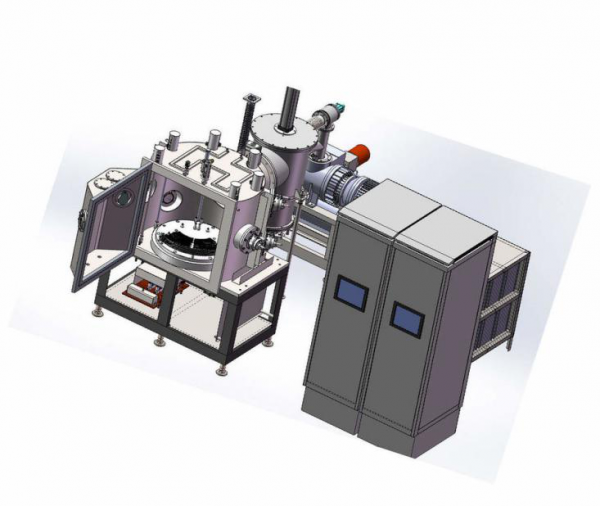

Whatsapp/Mobile: +86-19925343470 Email: adam@chinayibi.com Tel: +86-19925343470Physical vapor deposition (PVD) describes a variety of vacuum deposition methods which can be used to produce thin films and coatings. PVD uses the physical deposition to deposit a coating on the surface. The most common PVD processes are sputtering and evaporation. PVD is carried out in a closed ultra-low pressure vessel, which is a physical process.

By varying the gases and duration of the process, a range of colors is produced by Physical Vapour Deposition on stainless steel. The resulting colored stainless steel product can appear as brass, bronze, and other metals or alloys.

1. PVD coatings are sometimes harder and more corrosion resistant than coatings applied by the electroplating process. Most coatings have high temperature and good impact strength, excellent abrasion resistance and are so durable that protective topcoats are almost never necessary.

2. Ability to utilize virtually any type of inorganic and some organic coating materials on an equally diverse group of substrates and surfaces using a wide variety of finishes.

3. More environmentally friendly than traditional coating processes such as electroplating and painting.[citation needed]

4. More than one technique can be used to deposit a given film.

1. Specific technologies can impose constraints; for example, the line-of-sight transfer is typical of most PVD coating techniques, however, there are methods that allow full coverage of complex geometries.

2. Some PVD technologies typically operate at very high temperatures and vacuums, requiring special attention by operating personnel.

3. Requires a cooling water system to dissipate large heat loads.

For more information, Please visit the Stainless Steel Jewelry Manufacturer.